More than 30,000 people have taken our electric utility training classes.

“Awesome! Best training class I’ve done in a long time.”

— LG&E Utility Human Resources Manager

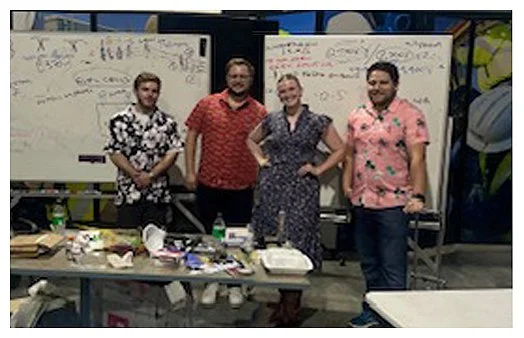

Pictured: Electric utility personnel who recently took EUSO and EDS.

From left to right:

Justin, Energy Management Systems Admin;

Nick, Engineering Design Technician, Distribution Department;

Natalie, Air Emissions Technician/Engineer;

Brandon, Energy Management System Admin

Why are PTS courses so highly rated?

Our electric utility training courses are the most attended of their kind in the industry for over 40 years.

There’s a reason electric utilities and businesses continue to choose PTS. Our classes and content are unparalleled in scope.

Our mission is to help people from both technical and non-technical backgrounds better understand how utilities work.

Across all occupation types, including veterans and rookies, PTS classes have an average rating of 9.7 out of 10. Find out why so many people value these classes.

Featured Electric Utility Training Courses

Upcoming Class

2-Day EUSO in Eugene, Oregon, June 16-17, 2026.

Hosted by Emerald People’s Utility District.

Register Now!

Electric Utility System Operations Course

Available as a 1-day, 2-day, or 3-day course designed for those who will benefit from a deep dive into how electric utility systems operate. EUSO is a prerequisite for courses like EDS and GRID.

Electric Distribution Systems Course

An in-depth follow up course to EUSO, this 2-day course is designed for utility personnel who work in the technical engineering, construction, maintenance and operations side of a utility.

Electrical Utility Business Operations Course

An in-depth, 1-day course designed for all utility personnel that will benefit from better understanding the industry and business side of electric utilities.

SCADA Training 101 Course

Take an in-depth journey through the world of SCADA systems and utility control systems. This course is conducted in two format: online webinar training or location-based training.

Contact Us

Interested in taking classes or setting up in-person classes at your utility or company?

Please provide your contact details and we will be in touch shortly!

Customers that have taken PTS utility training courses.